The loads include hydrostatic pressure, axial tension, and bending. A subsea riser or pipeline is exposed to different loads during installation from a laying vessel depending on the installation methods. The towing is either on the water surface (surface towing), at a controlled depth below the surface (control depth towing method ), or on the sea bottom (bottom towing), where the different water depths are used mainly to reduce the fatigue damage due to wave action.

The installation analysis can be divided into two stages: static analysis without any environmental loading, and dynamic analysis with environmental loading such as current and wave. The objective of the detailed installation analysis is to provide a step-by-step analysis to aid in the generation of the equipment deployment procedure.

Can orcaflex do pipe in pipe analysis software#

Finite element software (e.g.,Orcaflex) is used for the installation analysis. Analysis of subsea structure deployment provides the maximum allowable sea states and maximum expected cable tensions and the motions of installed equipment during installation.

Can orcaflex do pipe in pipe analysis verification#

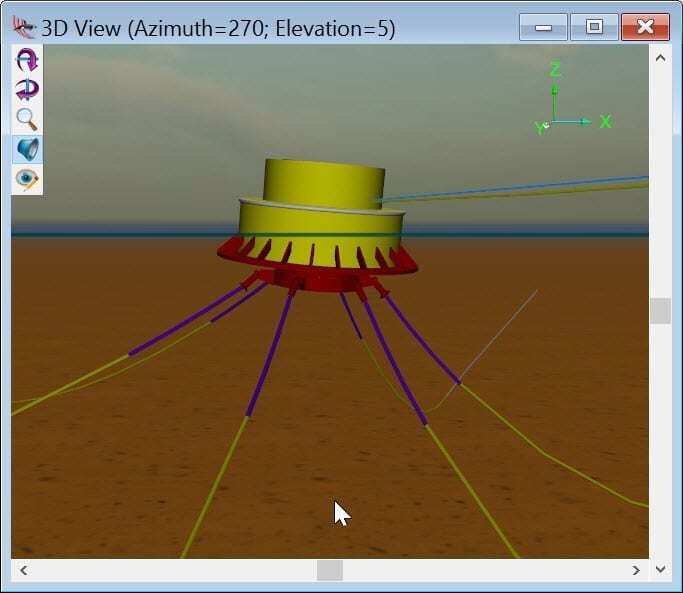

This article describe only the structure deployment analysis, which may be the most critical analysis for subsea installation, while other analyses such as barge strength verification for transportation and lifting analysis for loadout, are not included in this article. Deployment, typically including overboarding, splash zone lowering, midwater lowering, landing, and positioning and setting.The subsea structure installation procedure normally includes the following: Sketch of Analysis Steps for Typical Subsea Structure The minimum required data for an installation analysis normally include: (1) subsea equipment deployment installation, The subsea installation can be categorized into three types of installation The preliminary installation analysis is just used for some critical installation activities such as SPS splash zone lowering and pipeline installation at maximum water depth to prove the feasibility/ capability of the vessel and equipment, whereas the detailed installationĪnalysis is designed to provide a step-by-step analysis of the SPS installation. (2) detailed installation analysis of the engineering design with the goal of developing and installation procedure and relevant installation drawings. (1) preliminary installation analysis of the front-end engineering design (FEED) for determining the installation method, installation vessels and equipment, as well as the relevant installation duration and cost estimations, and

Installation analysis can be divided into two categories based on different phases of installation engineering: Installation analysis is a type of calculation for the validation of lifting capacity, strength capacity for lifting objects and vessel structures, etc.

0 kommentar(er)

0 kommentar(er)